Hydraulic elevator is a kind of elevator equipment composed of walking mechanism, hydraulic mechanism, electric control mechanism and support mechanism. The hydraulic oil is formed by the vane pump to a certain pressure, and enters the lower end of the hydraulic cylinder through the oil filter, flameproof electromagnetic reversing valve, throttle valve, hydraulic control check valve and balance valve, so that the piston of the hydraulic cylinder moves upwards and lifts the weight. The oil returned from the upper end of the liquid cylinder is returned to the fuel tank through the explosion-proof electromagnetic reversing valve, and its rated pressure is adjusted through the overflow valve, and the reading value of the pressure gauge is observed through the pressure gauge. Hydraulic lift is composed of oil tank, hydraulic oil gear pump, one-way valve, solenoid valve and hydraulic cylinder.

Start the hydraulic oil gear pump to continuously pressurize the hydraulic oil in the tank to the hydraulic cylinder along the pipeline pump, and the plunger in the hydraulic cylinder (connected to the bed surface) rises. In the way of ascending; when descending, just turn on the solenoid valve to open the return circuit, the oil returns to the oil tank, the hydraulic cylinder is decompressed, and the plunger descends.

The hydraulic oil is formed by the vane pump to a certain pressure, and enters the lower end of the hydraulic cylinder through the oil filter, flameproof electromagnetic reversing valve, throttle valve, hydraulic control check valve and balance valve, so that the piston of the hydraulic cylinder moves upwards and lifts the weight. The oil returned from the upper end of the liquid cylinder is returned to the fuel tank through the explosion-proof electromagnetic reversing valve, and its rated pressure is adjusted through the overflow valve, and the reading value of the pressure gauge is observed through the pressure gauge.

The piston of the hydraulic cylinder moves downward (ie, the weight drops). The hydraulic oil enters the upper end of the hydraulic cylinder through the explosion-proof electromagnetic reversing valve, and the return oil at the lower end of the hydraulic cylinder returns to the fuel tank through the balance valve, hydraulic control check valve, throttle valve, and explosion-proof electromagnetic reversing valve. In order to make the heavy objects descend smoothly and the braking is safe and reliable, a balance valve is set on the oil return road to balance the circuit and maintain the pressure, so that the descending speed is not changed by the heavy objects, and the flow rate is adjusted by the throttle valve to control the lifting speed.

In order to make the braking safe and reliable and prevent accidents, a hydraulic control one-way valve, namely a hydraulic lock, is added to ensure safe self-locking when the hydraulic pipeline bursts unexpectedly. An overload sound alarm is installed to distinguish overload or equipment failure.

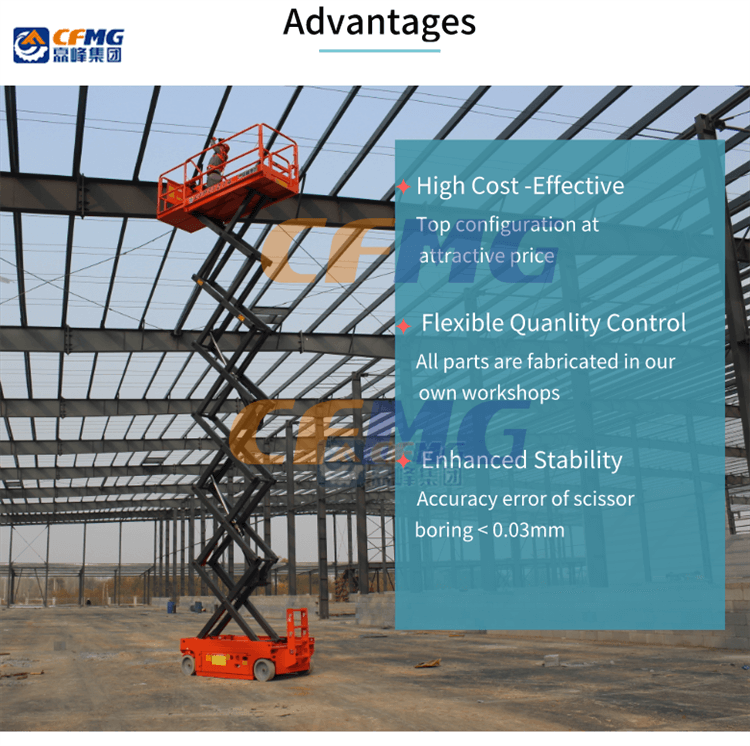

The hydraulic lifting platform mainly realizes the lifting function through the pressure transmission of hydraulic oil. Its scissor fork mechanical structure makes the lifting of the lift have high stability, wide working platform and high bearing capacity, making the working range at high altitude Larger and suitable for multiple people to work at the same time. It makes aerial work more efficient and safer.

Post time: Apr-21-2022